The Atlas Group > Capabilities > Chemical Milling & Phosphoric Acid Anodizing

Chemical Milling & Phosphoric Acid Anodizing

The world’s largest OEMs rely on the quality of The Atlas Group’s precision metal parts. That’s why we maintain our processing capabilities at the leading edge of the industry’s best practices for milling and chemical processing.

The Atlas Group is fully equipped with a state-of-the-art phosphoric acid anodizing line. The line features 25’ long x 8’ deep x 3’ wide tanks with the ability to run multiple flight bars. A 3,000-square-foot, controlled contamination area dedicated for adhesive prime application and curing includes a 30’ x 15’ down-shaft spray booth and independent curing oven.

Throughout The Atlas Group’s facilities, our most important asset is our people. Highly trained, experienced and forward-thinking, the employees of each Atlas Group company are dedicated to the success of our customers.

Strong partnerships are the basis of The Atlas Group’s success, and our philosophy of vertical integration provides customers the benefits of our true start-to-finish manufacturing, from materials to engineering, testing to production, all within budget and deadline.

Learn more about the companies that make up The Atlas Group.

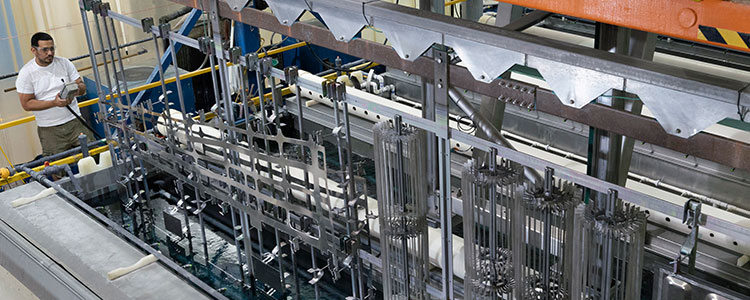

Phosphoric Acid Anodizing Line

The Atlas Group is fully equipped with a state-of-the-art phosphoric acid anodizing line. The line features 25’ long x 8’ deep x 3’ wide tanks with the ability to run multiple flight bars.

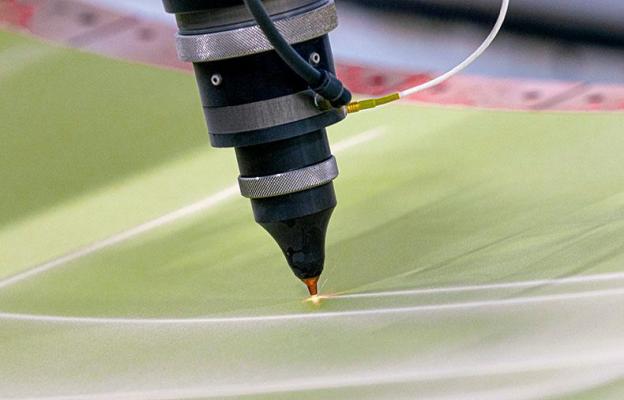

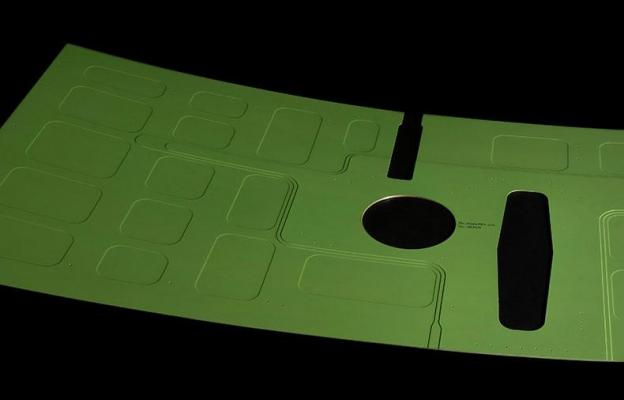

Chemical Milling & Laser Scribe

The chemical milling process selectively removes material while maintaining structural strength where needed. Material weight reductions of 75 percent or more and thickness reductions down to 0.010”or less produce super-lightweight yet strong parts.

We also offer a fully automated 5-axis CNC laser scriber, providing consistent and repeatable chemical milling pocket cutouts.

Adhesive Prime and Cure

Our consistently expanding capability line includes modern adhesive priming and curing facilities, featuring a 3,000-square-foot controlled contamination room and a newly expanded 6,400-square-foot clean room.

- Dedicated 13' x 30' cure oven

- 40' x 40' clean core machining area

- 5-axis Anderson Stratos CNC router

Chemical Processing Approvals

Our safety and quality procedures are among the most robust in the industry, following a rigorous approval process including functional use classes such as:

• Chelating and sequestering agents

• Colorants, polymers, preservatives and related chemicals

• Enzymes and enzyme stabilizers

• Oxidants and oxidant stabilizers