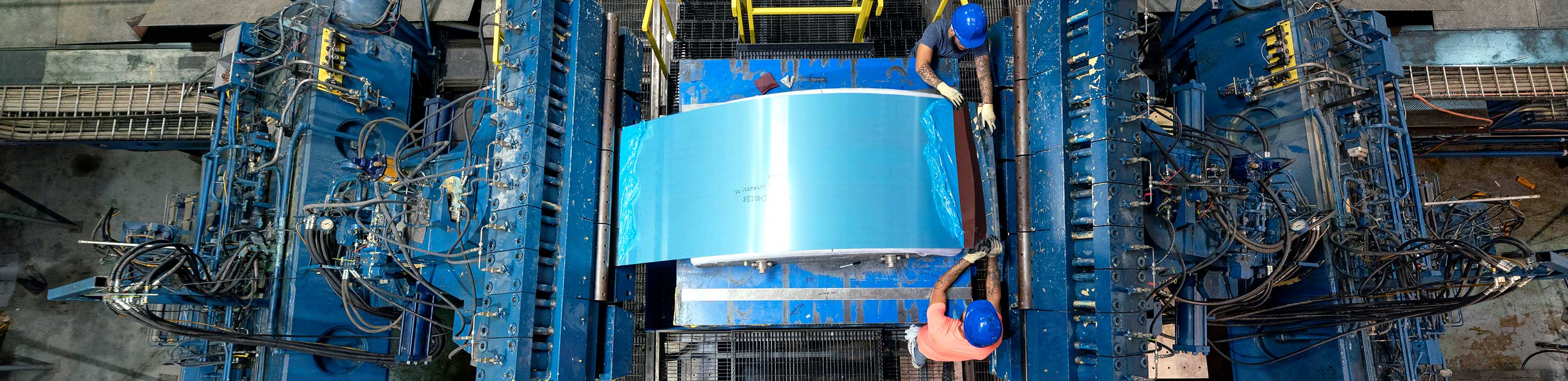

Skin Manufacturing

Our custom sheet metal services offer a cost-effective, on-demand, one-stop shop for skin manufacturing. Whether you're looking for specialized engineering designs, or simply need standard-gauge metal bent, punched or cut, The Atlas Group is prepared to meet your high-volume production requirements.

Stretch Form Specifications include:

- Mag Working Envelope 118.1” x 59.1” x 39.4”

- Mag EX Working Envelope: 157” x 59.1” x 39.4”

- Mag EX W Working Envelope: 157” x 72” x 39.4”

- Sheet length capability: 480” (720” with extensions)

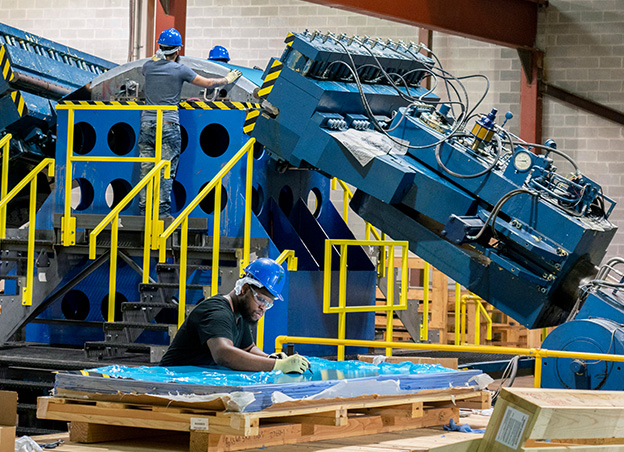

Sheet Metal Equipment includes:

- Drop hammers: 48” x 67”

- Hydro presses: 30” x 70”

- Press brakes: 136”

- Blanking presses: 35” x 55”

- Roll forming up to 120”

Learn more about the companies that make up The Atlas Group.